Project Description

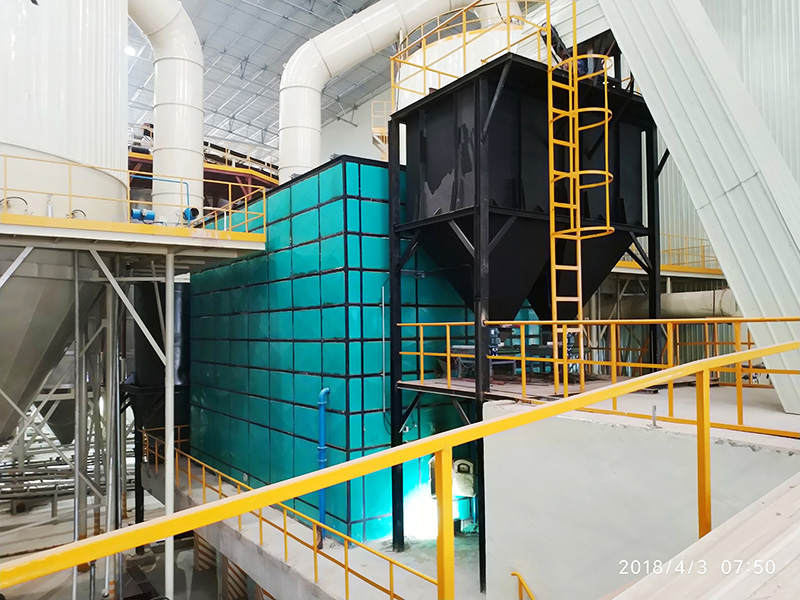

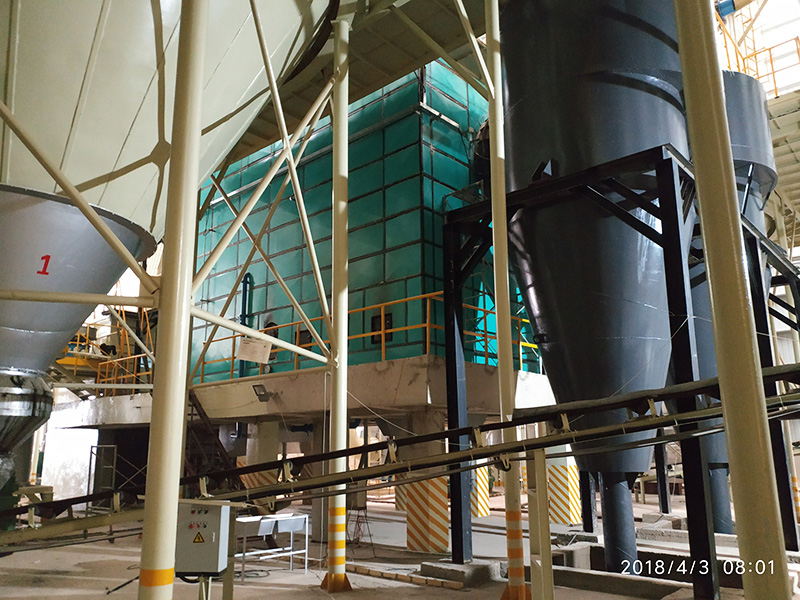

XTL biomass hot stove

XTL biomass hot stove

XTL biomass hot blast stove is a new type of combustion equipment developed by our company for biomass fuels. It has stable heating, reliable operation, convenient operation, low ash content, low sulfur, chlorine and nitrogen content, low calorific value, low density and other characteristics of biomass fuels.

Biomass overview

Biomass refers to the use of atmosphere, water, land and other organisms produced by photosynthesis, that is, all living organisms can grow known as biomass. It includes plants, animals and microorganisms。

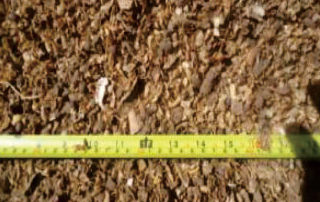

Broad concept: biomass includes all plant microorganisms and the animals that feed on them, as well as the waste produced. Representative biomass such as crops, crop waste, wood, wood waste and animal waste.

Narrow sense: biomass mainly refers to the agricultural and forestry production process in addition to food, fruit straw, trees and other lignocellulose, agricultural products processing industry waste, agricultural and forestry waste and livestock manure and waste in the production process of animal husbandry. Characteristics: renewable, low pollution, widespread distribution.

Species and characteristics of biomass

Moisture content, volatile content, ash content, calorific value, density, particle size

Combustion technology method and characteristics

Environmental protection, efficiency, power consumption, investment cost

Biomass direct combustion: layer burning technology, easy sintering, low efficiency. Fluidized bed technology, high combustion efficiency.。

Mixed combustion of biomass and coal: national environmental protection is not allowed, eia is not pass

Biomass molding fuel combustion: compression molding equipment technology is not mature, large energy consumption.

Biomass carbonization after combustion: increase carbonization equipment, early investment is large, equipment needs maintenance. Temperature, time, fly ash

Combustion process and difficulty

Time, temperature, fly ash

Preheating and drying–Volatilization is analyzed, combustion starts, and coke forms –Residual coke combustion

1、The moisture content is high and changeable, the calorific value is low, the calorific value before furnace changes quickly.

2、Small density, high voidage, loose structure, large windward area, large proportion of suspended combustion.。

3、High volatile content, low precipitation temperature, rapid precipitation process, combustion risk control needs to be accurate

4、Easy to ignite, difficult to burn out, alkali metal and chlorine corrosion problems

5、 High moisture Density is small High volatile Short stay

6、Corresponding difficulties

7、The heat supply is unstable Difficulty in conveying and feeding Combustion instability Low burning rate