Project Description

Two-section coal gas generator

Two-section coal gas generator

Compared with one-section gas generators, two-section gas generators have higher carbonization and desiccation sections. The height of the furnace is more than 15m and has two gas outlets, down and up respectively.

The heat value of coal gas from the upper outlet is about 1600-1700 Kcal/m3, the temp-erature is 120-180℃. It is called hot and dusty gas.The dust in desiccation layer and Ch⁴, alkene and coal tar created in carbonization layer by the decomposed volatiles of the coal will all be discharged from the upper outlet. The heat value of the coal gas from the lower outlet is around 1250-1350 Kcal/m³, and the temperature is 550-650℃. This is hot and clean gas without tar and dusts.

When using weakly-caking bituminous coal to produce gas, we can get low-temperture tar and light oil. The out put rate of tar is 3-5% of the coal when the coal volatiles are about 25-32%.

When the two-section gas generator is operating with full materials, there is no strike from the falling raw materials, and the eduction of the coal is not obvious. For the thick raw materials layer, high carbonization and desiccation layer, and sufficiently carbonization, the coal can be well formed semi-coke, which can produce gas with high net heat value.

The thicker the raw materials layer is, the more inactive it is big and the inner furnace resistance is bigger, which can ensure less operation failure.

Two Stages Coal Gasifier Specfication

Type |

CG3Q3.2-1 |

|---|---|

| I.D.Df chamber(mm) | 3200 |

| Chamber cross-section area (m2) | 8.04 |

| Heat perception area of water jacket (m2 ) | 17 |

| Applicable coal | Non-caking or weak-caking bituminous coal |

| Coal size(mm) | 20~40; 25~50; 30~60 |

| Coal consumption(kg/h) | 2000~2500 |

| Air consumption (m /kh2·煤) | 1.5~2.5 |

| Steam consumption (m /kh2·煤) | 0.3~0.5 |

| Gas output (m /h 3 ) | 6000~7500 |

| Net heating value (KJ/m3 ) (Up stage) 段(Down stage) |

7110~7350 5225~5434 |

| Gas pressure(KPa) (Up stage) 段(Down stage) |

1.5~3.0 2.0~4.0 |

| Max.blast pressure(KPa) | 7.5 |

| Saturated temperature(℃) | 50~65 |

| Steam seal pressure of poking hole(KPa) | <294 |

| Steam products (kg/h) | 550 |

| Inner steam pressure(MPa) | <0.294 |

| Coal feeding system | Compressed air or hydraulic driving |

| Ash tray driving power (KW) | 5.5 |

| Discharging ash mode | Automatic wet discharging ash |

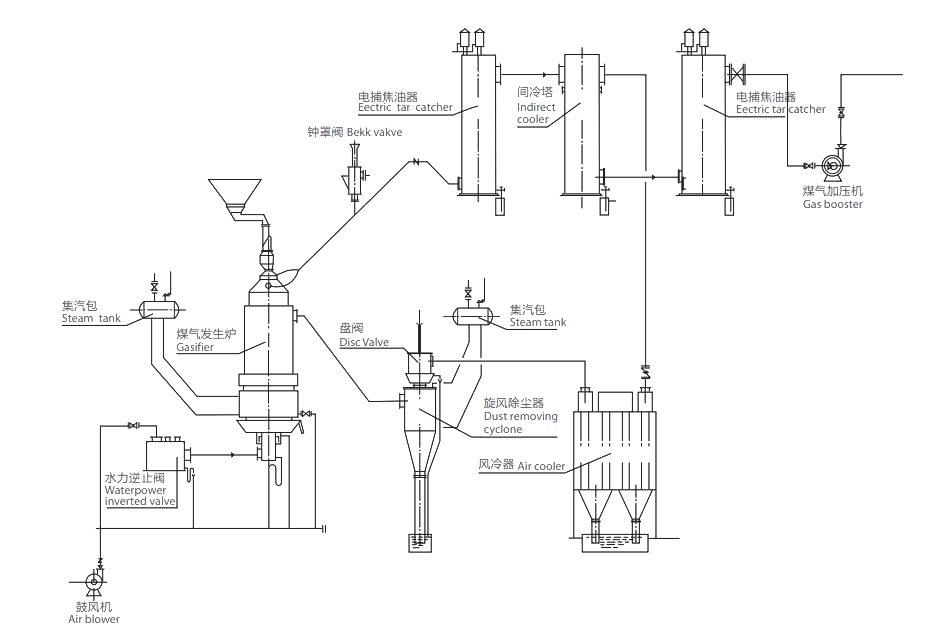

Two Stage Coal Gasifier Cold Gas Process Flow Diagram

Leave A Comment