Project Description

Shaped coal

Shaped coal

To popularize civilian clean coal and industrial shaped coal for industrial kilns is an important measure for prevention and control of coal smoke pollution and saving coal energy. By 2000, the use of smell coal would be stopped in the major cities, and smokeless lump coal used by the small and medium size fertilizer producers and the lump coal used in the gas producing stoves will be gradually limited and replaced by shaped coal. As the shaped coal has the characteristics of uniform size, high aperture ratio, strong reaction and thermal change, particularly modified and optimized feature, the shaped coal can achieve the results such as reduction of viscidity, melting retardation, increase of reaction activity, improvement of thermal stability and mechanical intensity, solidification of sulfur and elimination of smoke after forming techniques of blending, additive, fast heating and heat smothering are adopted. It is greatly conducive to expanding coal application, making full use of local coal resource, reducing charging cost, improving environment and preventing pollution.

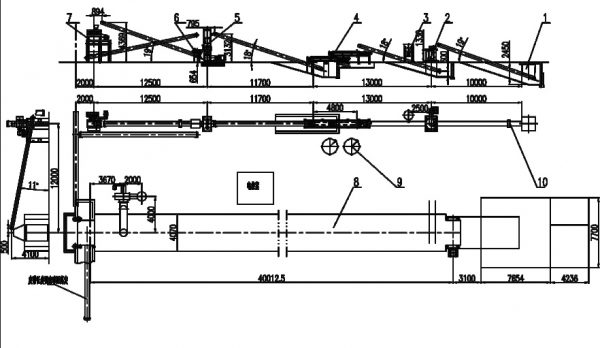

Schematic diagram for technological process of shaped coal production line

Vertical crusher

The crusher of this series adopts vertical structure and classified crushing with simple structure, simple operation, low energy consumption and less dust. Since it has no sieving plate, jams can be avoided. The hammer head adopts hinge structure and can be replaced easily. The hammer head and scaleboard are made of high alloy wearable material with high intensity and wearability and long service life

Technical parameters

| Type | PCL-550 | PCL-700 | PCL-1000 | PCL-1250 | PCL-1500 |

| Rotor diameter(mm) | 550 | 700 | 1000 | 1250 | 1500 |

| Feed grain size(mm) | 20 | 20 | 20 | 20 | 20 |

| Discharging rain size(mm) | <3 | <3 | <3 | <3 | <3 |

| Throughput(t/h) | 3~6 | 8~12 | 15~22 | 23~35 | 33~50 |

Homogenizer

After kneading, the adhesives and coal grains are mutually inclusive and strongly plastic, but it may cause agglomerate phenomenon. Uneven density

due to loose stack may lead to uneven density and intensity during the formation of coal balls. So the material must be homogenized before forming in order to improve its uniformity of density and intensity. The homogenizer developed by our plant through years’ practical operation is designed for homogenizati on of materials. The high running speed of the homogenizer can break up the agglomerates of materials and achieves, and ensure the unifor-mity of various compositions

Technical parameters

| Type | Annual output(10,000 tons) | Total power(KW) |

| JH700 | 5 | 22 |

| JH1000 | 10 | 45 |

CFJ series electromagnetic iron separator

This product is specially designed for belt conveyor with width of 500mm and 650mm. It is used to eliminate magnetic iron during blending or conveying to avoid damage of equipment due to access of iron.

Technical parameters

| Type | CFJ-500 | CFJ-500A | CFJ-650 | CFJ-650A |

| Voltage | -98V | -198V | -198V | -198V |

| Current | 2.3A | 2.1A | 2.1A | 2.1A |

| Power | 220W | 400W | 400W | 800W |

| Effective attraction height | 0~120mm | 0~150mm | 0~170mm | 0~250mm |

| Applicable belt width | B500 | B500 | B650 | B650 |

| Attraction force | 20kg | 30kg | 30kg | 50kg |

Forming machine

The feeding inlet of forming machine adopts mechanical pushing device which is applicable for charges of different viscidity. It can avoid material accumulation and ensure uniform distribution. The inlet is provided with a regulating plate for adjusting feeding volume, ensuring that the compacting ratio of the materials are with in the specific range, thus it has high forming ratio and good intensity.

Technical parameters

| Type | Diameter of forming roller (mm) |

Width of forming Roller(mm) |

Power of motor(kw) | Unit linear pressure | Annual output (10,000tons) |

| CXJ5 | 600 | 375 | 18.5 | 0-2.5t/CM adjustable | 5 |

| CXJ10 | 650 | 680 | 30 | 0-2.5t/CM adjustable | 10 |

| CXJ20 | 1000 | 900 | 90 | 0-2.5t/CM adjustable | 20 |

| CXJ30 | 1200 | 1100 | 132 | 0-2.5t/CM adjustable | 30 |

WHG series horizontal drying machine

The horizontal drying machine made by our plant eatures low energy consumption, stable and reliable running and satisfying drying effect with average dewatering rate at 9-10%.

Technical parameters

| Type | Layer number | Annual output (10,000 tons) | Power of motor (kw) |

| WHG-50 | 2 | 5 | 7.5 |

| WHG-50(Double) | 4 | 10 | 11 |

| WHG-75(Double) | 4 | 15 | 22 |

| WHG-80(Double) | 4 | 20 | 30 |